Acoustic Groove panels

AED 150 per sq.m | In stock

Size: Available in different size

Thickness: 12 mm & 24 mm

Color: Available in different colors.

Shape: Shape can be customize accordingly

Installation: Wall or Ceiling Installation

Acoustic Groove Panels are advanced sound-absorbing panels designed to enhance acoustic quality while adding a modern, stylish aesthetic to any interior space.

These panels are crafted with precision grooves that help diffuse and absorb sound, making them ideal for controlling noise levels and reducing echo in offices, auditoriums, homes, and more.

With their sleek design and high-performance sound control, they are a perfect combination of form and function.

Features of Acoustic Groove Panels

- Pre Cut

- Cutomizable

- Fire resistant

- Stylish Design

- Multiple Colors

- Amazing patterns

- Easy Installation

- Durable Construction

- High sound absorption

- Eco-friendly material

- Versatile applications

- High Acoustic Performance

Applications of Acoustic Groove Panels

- Corridor

- Airports

- Gymnasium

- Auditorium

- Classrooms

- Piano Room

- Restaurants

- Banquet hall

- Meeting room

- Concert Hall

- Home Theaters

- Assembly Hall

- Art Galleries

- Worship Spaces

- Shopping Malls

- Medical Clinics

- Reception Areas

- Exhibition Halls

- Conference Rooms

- Recording Studios

- Corporate Lounges

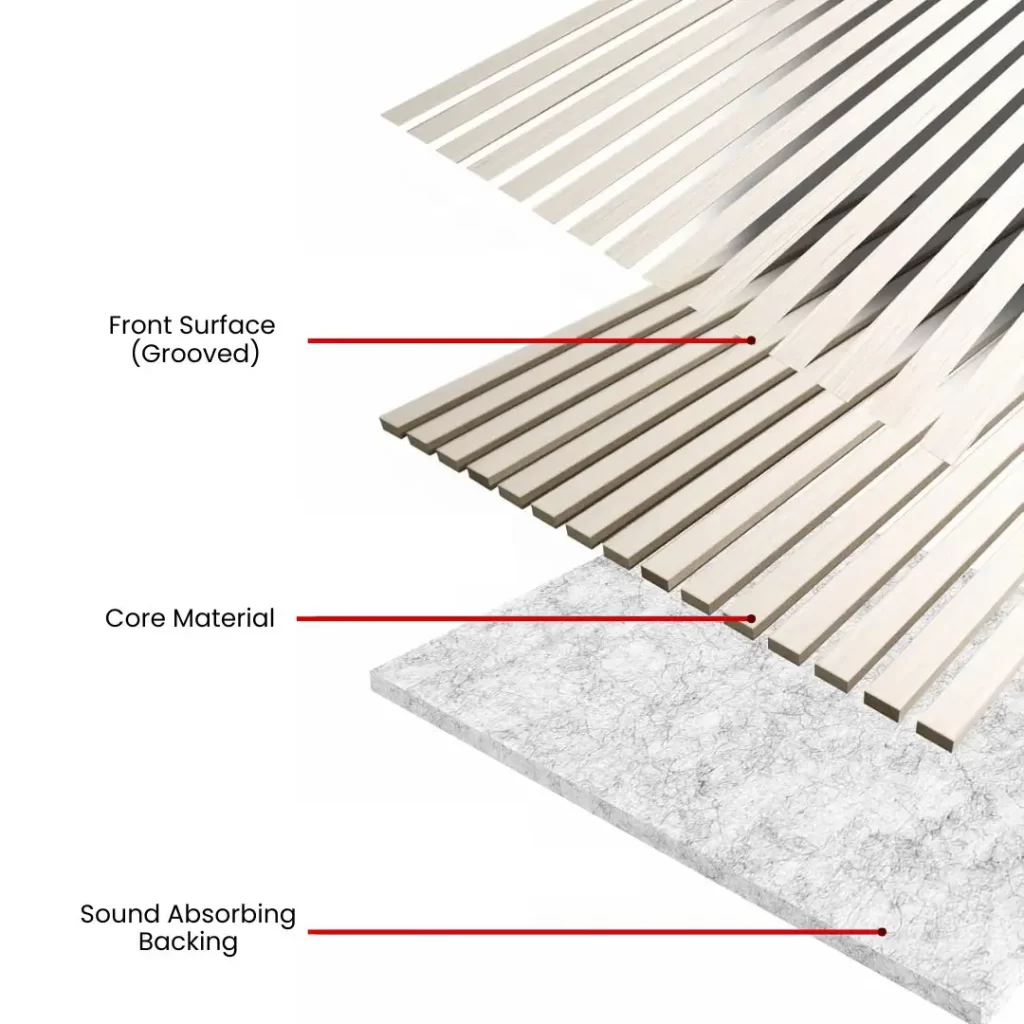

Components of Acoustic Groove Panels

Grooved Surface

The front of the panel is patterned with grooves and slots. These grooves are strategically designed to capture and dissipate sound waves, which helps reduce reverberation.

Core material

The main body of acoustic groove panels is often made from MDF (Medium-Density Fiberboard) or HDF (High-Density Fiberboard). These materials are chosen for their stability, strength, and ease of manufacturing.

Sound-Absorbing Backing

Behind the MDF core, an acoustic felt or foam layer is applied. This material absorbs sound that passes through the grooves, helping to further reduce noise. Felt is often made from recycled fibers, making it an eco-friendly option that also enhances sound absorption.

FAQ'S About Acoustic Groove Panels

Acoustic groove panels are used to improve sound quality and reduce noise by absorbing and diffusing sound, making them ideal for spaces like studios, theaters, offices, and public venues.

Acoustic groove panels are used to improve sound quality and reduce noise by absorbing and diffusing sound, making them ideal for spaces like studios, theaters, offices, and public venues.

Typically, acoustic groove panels are made from MDF or HDF with a grooved surface, backed with felt or foam for sound absorption, and finished with wood veneer or laminate.

Yes, they come in various sizes, finishes, and groove patterns, allowing customization to suit different aesthetic and acoustic requirements.

They are commonly installed in spaces requiring sound control, like concert halls, home theaters, conference rooms, restaurants, and offices.

Many panels use recycled materials, especially for the backing layer, making them an eco-friendly choice for soundproofing.

No, they are generally low-maintenance. Regular dusting or light cleaning with a soft cloth is usually enough.